Pierre’s page where he can put whatever the heck he wants. It can stay here permanently and doesn’t have comments.

Swiss Rifle Central – Swiss Products USA – link – link

- The Swiss Rifles Message Boards

- The Swiss Weapon Board – At Gunboards.com

- The Straight-Pull Forum – At Milsurpshooter.net

- The Swiss Rifle Forum – At the Curios and Relics Forum

- Swiss Rifle Forum – At Suplusrifle.com

- The SIG Forum – Includes a discussion section about SIG Rifles.

- Biggerhammer.net’s SIG AMT and 550 Discusion Board – A very good source for Swiss Stgw.57 and Stg.90 discussion.

- Swiss Rifles – At Milsurps.com

- Swiss Arms – At the Gun and Game Forums

- Swiss Rifles – At Milsurp After Hours

- SIG – K11 – K31 – At The Long Distance Forum (French may require registration)

- K31 E-Space – (Spanish)

- Swiss Lugers – Located at the Lugerforum.com a good resource for all Luger owners

Swiss Rifle and Parts Sources

Other Related Links

- The Swiss Shooting Federation – The Swiss organization devoted to the cause of Swiss marksmanship.

- ProTELL – A Swiss organization devoted to protecting the rights of Swiss Gun Owners. Site is in German, French, and Italian. Membership form is in English.

- The Swiss Gun Collectors Association – An organization dedicate to the historical preservation of Swiss Gunmaking.

- Rust and Verdigris – a Swiss Army Re-Enactors site with numerous pictures and lot’s of information. It’s in German, but worth a visit.

- Swissguns.ch – A Swiss Firearms site. (In French)

- A Visit to the Swiss Military Museum at Morges – Great pictures of a wide variety of Swiss Weapons.

- The Festungsmuseum Reuenthal – A real Swiss Fort converted to a museum, mostly in German, but some text in English.

- The Tir Fédéral 2000 – An article about the world’s largest shooting competition, held in Bière, Switzerland.

- The Swiss Embassy Webpage

- The Swiss Guard Homepage – Swiss Mercenaries charged with protecting the Pope and the Vatican.

- The SIG SAUER Homepage – Also visit their European Page

- The Swiss Military Net– The Swiss Military Website.

- A Swiss Rifle Club – Includes images of most the rifles listed in the history section (in German)

Manufacture Dates:

To determine the date of manufacture of a particular rifle, one needs to know both the model and the serial number. Given the model,

go to the appropriate table and look for the range of serial numbers that spans the given serial number. The corresponding date for

that serial number is shown in the left column of the table.

For example, given a Model 1911 with a serial number of 2673xx, the tables show no such serial number for a Model 1911. There is a

range spanning this serial number for a Model 1889/96, however, showing a manufacture date of 1900. Knowing that the M89/96s

were converted to approximate the M1911 form, we conclude that this rifle is a Model 1889/96/11 manufactured in 1900.

As another example, given a Model 1931 with a serial number of 9999xx, the tables indicate that this rifle was manufactured in 1953.

Note: Some rifles will have an uppercase P either after or below the serial number. Upon retirement from active duty, the retiring Swiss

soldier was given the opportunity to keep his service rifle. Rifles so obtained were stamped with the uppercase P near the serial

number, and should not be confused with the “Private” series of rifles indicated in the tables below. The “Private” series of rifles were

manufactured to fill special orders with the factory (such as for export).

[b]Model 1889 – Training Rifles (Instruktionsgewehre)[/b]Year Quantity Serial numbers

1893 40 E1-E39 (E20 doubled)

1895 2 E43, E45

1896 2 E42, E44

[b]Model 1889 – Repeating Rifles (Repetiergewehre) Manufacture ended on April 29, 1897[/b]

Year Quantity Serial numbers

1891 24900 1-24900

1892 90100 24901-115000

1893 59100 115001-174100

1894 8787 174101-174887 175001-183000

1895 12500 183001-195500

1896 12500 195501-208000

1897 4000 208001-212000

Year Quantity Serial numbers

1896 250 4251-4500

1897 250 4501-4750

1898 250 4751-5000

1899 250 5001-5250

1900 400 5251-5650

1901 500 5651-6150

1902 500 6151-6650

1903 500 6651-7150

1904 300 7151-7450

1905 300 7451-7750

1895-1905 96 P1-P96 – Private series,numbers P46-P84 for a commercial company, Paris

1897-1903 11 E1-E11, extra series,entry in the export book of Waffenfabrik Bern

Year Quantity Serial numbers

1897 2 E2-E3

1899 4 E4-E7

1900 4 E8-E11

1904 4 E12-E15

1908 4 E16-E19

Year Quantity Serial numbers

1895 50 1-50

1897 9000 212001-221000

1898 15500 221001-236500

1899 15500 236501-252000

1900 16500 252001-268500

1901 11500 268501-280000

1902 12000 280001-292000

1903 10000 292001-302000

1904 8000 302001-310000

1905 6000 310001-316000

1906 6000 316001-322000

1907 5000 322001-327000

1908 5000 327001-332000

1909 4800 332001-336800

1910 6300 336801-343100

1911 1900 343101-345000

1912 4000 345001-349000

Year Quantity Serial numbers

1899 18 E1-E18

1900 6 E19-E24

1901 9 E25-E33

1902 3 E34-E36 (P9+P34?)

1903 2 E37-E38

1904 1 E39

1907 1 E40 (P40)

Year Quantity Serial numbers

1898 2100 1-2100

1899 1649 2101-3749

1900 1580 3750-5329

1901 499 5330-5828

1902 193 5829-6021

1903 232 6022-6253

1904 151 6254-6404

1905 114 6405-6518

1906 183 6519-6701

1907 150 6702-6851

1908 82 6852-6933

1909 37 6934-6970

1910 236 6971-7206

1911 99 7207-7305

1912 115 7306-7420

1914 231 15001-15231

1915 33 15232-15264

1916 70 15265-15334

1918 2 15335-15336

1924 26 15337-15362

1925 20 15363-15382

1926 80 15383-15462

1927 15 15463-15477

1898-1919 45 P1-P45, Private series entry in the export book of Waffenfabrik Bern

[b]Model 1889/1900 Short Rifles (Kurze Gewehre)[/b]Year Quantity Serial numbers

1901 5000 1-5000

1902 885 5001-5885

1903 915 5886-6800

1904 1000 6801-7800

1905 1500 7801-9300

1906 1500 9301-10800

1907 1750 10801-12550

1908 1750 12551-14300

1909 1650 14301-15950

1910 1500 15951-17450

1911 1300 17451-18750

? 176 P1-P176 [sic],

Private series,entry in the export book of Waffenfabrik Bern

1903 Zoll 89 P72-P150

1904 Zoll 300 P173-P472

? 50 P501-P550

Zoll 394 P551-P944

Zoll 190 P951-P1140

Zoll 103 P1141-P1243

Note: Zoll – Customs service

Year Quantity Serial numbers

1906 810 1-810

1907 2790 811-3600

1908 2600 3601-6200

1909 500 6201-6700

1910 600 6701-7300

1911 600 7301-7900

1906-1914 39 P1-P39, Private series,entry in the export book of Waffenfabrik Bern

were modified[/b]

Year Quantity

1912 5000

1913 40000

1914 51000

1915 38000

1916 1500

1918 200

1919 50

1920 20

Year Quantity Serial numbers

1912 6000 355001-361000

1913 14000 349001-355000 361001-369000

1914 5000 369001-374000

1915 22000 374001-396000

1916 32000 396001-428000

1917 31000 428001-459000

1918 20000 459001-479000

1919 3000 479001-482000

? 200 P5000-P5200, Private series,last manufactured on October 10, 1919,entry in the export book of Waffenfabrik Bern ? 1 P5219 ? 698 P5251-P5948

[b]Model 1911 Carbines (Karabiner) Manufacture ended on July 11, 1933[/b]Year Quantity Serial numbers

1914 6000 30001-36000

1915 4000 36001-40000

1916 13000 40001-53000

1917 16100 53001-54400 55001-62000* 62301-70000**

1918 19000 70001-89000

1919 2000 89001-91000

1920 6500 91001-97500

1921 8500 97501-106000

1922 7500 106001-113500

1923 7900 113501-121400

1924 7600 121401-129000

1925 7500 129001-136500

1926 9900 136501-146400

1927 12600 146401-159000

1928 11500 159001-170500

1929 12800 170501-183300

1930 9900 183301-193200

1931 8800 193201-202000

1932 9200 202001-211200

1933 3900 211201-215100

1913-1919 300 P2001-P2300,

Private seriesentry in the export book of Waffenfabrik Bern Zoll 18 P2013-2030 Zoll 8 P2037-P2044 Zoll 30 P2071-P2100 Zoll 100 P2101-P2200 without entries 4 P2201-P2204 ? 19 P2205-P2223

Zoll 50 P2251-P2300

Notes:Zoll – Customs service* Serial numbers 54401-55000 and 62001-62300 are missing (900 pieces)** Serial numbers 69701-69750

have double entries, but are only entered once in this list. Consequently, the total of the Model 1911 Carbines listed here comes to

185150 pieces.

[b]Special Model 1911 Rifles (Extra-Gewehre)[/b]YearWhoSerial numbers

1915 Kriegstechnische Abteilung, Bern – E500

1914 Koenigliche Gewehrpruefungskommission, Ruheleben-Spandau -Spanische Gesandtschaft, Bern – E501E502

1919 Emile Galley, Lausanne – E503

1920 Hollaendische Gesandtschaft, Bern -Englische Gesandtschaft, Bern – E504E505

1915 Eidgenpessiosches Militaerdepartement, Bern – E506-E507

1917 Sektion fuer Munition, Thun – E508

1918 Amerikanische Gesandtschaft, Bern – E509

1919 Franzoesische Gesandtschaft, Bern – E510

1920 Franzoesische Kriegsministerium, Paris -Tiro Suizo, Buenos Aires – E511-E520E521-E522

1921 Italienische Gesandtschaft, Bern -Italienischer Militaerattache, Bern -Flugplatzdirektion, Duebendorf -Sektion fuer

Schiessversuche, Thun – E523 E524 E525 E526-E527

1922 Eidgenoessische Munitionsfabrik, Thun -Eidgenoessische Munitionsfabrik, Thun -Internationales Wettschiessen, Mailand -The

High Commissioner for the Commonwealth of Australia, London – E525? E528-E529 E530 E531

1923 Franzoesisches Kriegsministerium, Paris – E532

1924 Eidgenoessisches Schuetzenfest, Aarau -KTA, fuer Schweden -KTA, fuer Tschechoslowakei – E533-E534 E535 E536

1925 KTA, fuer Waffenfabrik Oviedo -KTA, Bern -Schiessschule Walenstadt – E537 E538-E539 E540-E541

1926 Afghanische Regierung (mit Dolch 18) -KTA, fuer Tschechoslowakei – E542 E543

1934 J. Alder W+F, Bern – E544

Notes:KTA – Kriegstechnischen Abteilung des schweizerischen MilitaerdepartementsW+F – Waffenfabrik

Year Who Serial numbers

1918 Amerikanische Gesandtschaft, Bern E1

1919 Amerikanische Gesandtschaft, Bern E2

1920 Hollaendische Gesandtschaft, Bern -Tiro Suizo, Buenos Aires -Tiro Suizo, Buenos Aires – E3E 5E6

1921 Direktion Eidgenoessische Waffenfabrik, Bern E7

1923 Franzoesisches Kriegsministerium, Paris E4

1926 Afghanische Regierung E8

1932 Wojskorny Zaklad, Warschau -Werkzeugmaschinenfabrik, Oerlikon – E9E10

1952 unreadable E11

[b]Model 1911 Carbines (Karabiner) Converted from Model 1889/1900 Short Rifles and Model 1905 Cavalry Carbines[/b]

Year Quantity

1913 1000

1914 8000

1915 8000

1916 8200

1917 900

1918 100

1919 70

1920 65

Year Quantity Serial numbers

1923 KTA, Bern V1-V10

1926 KTA, fuer Schiessschule Walenstadt V1-V200

Note: KTA – Kriegstechnischen Abteilung des schweizerischen Militaerdepartements

Year Quantity Serial numbers

1933 1193 520010-521202

1934 15534 521203-536736

1935 13664 536737-550400

1936 11326 550401-561727

1937 11639 561728-573366

1938 10344 573367-583700

1939 15300 583701-599000

1940 33575 599001-632575

1941 54150 632576-686725

1942 49350 686726-736075

1943 50475 736076-786550

1944 51900 786551-838450

1945 26200 838451-864650

1946 15600 864651-880250

1947 20950 880251-901200

1948 20100 901201-921300

1949 15500 921301-936800

1950 13200 936801-950000

1951 23050 950001-973050

1952 21400 973051-994450

1953 554 97450 994451-999 999215001-222450

1954 17150 222451-239600

1955 11250 239601-250850

1956 6400 250851-257250

1957 2950 257251-260200

1958 3130 260201-263330

Year Quantity Serial numbers

1934 16 ?

1935 500 400001-400500

1936 100 Zoll 401001-401100

1937 150 Zoll200 401101-401250400501-400700

1938 150 400701-400850

1939 20 401501-401520

1940 1505305050 400851-401000401521-402050402151-402220402251-402300

1941 300 402301-402600

1942 650 402501[sic]-403150[sic]

1943 350 403151-403500

1944 400 403501-403900

1945 600 403901-404500

1946 837 404501-405337

1947 92930 405322[sic]-406250E519767-E519796

1948 400 406251-406650

1949 650 406651-407300

1950 40050 407301-407700 408001-408050

1951 30050 407701-408000 408051-408100

1952 300 408101-408400

1953 45050 408401-408850 409051-409100

1954 200100 408851-409050 409101-409200

1955 450100 409201-409650 410151-410250

1956 450 409651-410100

1957 50300 410101-410150 410251-410550

1958 475 410551-411025

1959 425 411026-411450

1960 300 411451-411750

1961 300 411751-412050

1962 400 412051-412450

1963 50400 267331-267380412451-412850

1968- 1969 150 various numbers

1971 15050 269431-269580269881-269930

Stand (?) 1972 250 various numbers

Note:Zoll – Customs service

allocated for various purposes. See the K31 tables above for yearly records of specific serial ranges actually marked on receivers.]

Serial Numbers Allocation

215001-350000 K31 Carbine series, ordered by KTA for KMV

350001-400000 K31 Carbine series

P400001-P450000 Private K31 Carbine series

450001-500000 K31 Carbines with telescopic sights (sniper versions)

500001-500200 Trials versions

E519701-E519900 Various special K31s

519901-519999 Cutaway K31s (running backwards?), last number 519970

520001-520150 Carbine series ordered by KTA, delivered by W+F for special purposes

520081-520100 Ditto, reserved for W+F

520151-999999 Carbine series, ordered by KTA for KMV

after 550651 Hardened magazine boxes

after 540001 Hardened receivers

Notes:KTA – Kriegstechnischen Abteilung des schweizerischen MilitaerdepartementsKMV – KriegsmaterialverwaltungW+F –

Waffenfabrik

[b]Models 1931/42 and 1931/43 Sniper Rifles (Zielfernrohr-Karabiner)[/b]Year Quantity Serial numbers

1943 96 ?

1944 403 ?

1945 1537 ?

1946 205 ?

Year Quantity Serial numbers

1957 170 1001-1170

1958 3030 1171-4200

1959 800 4201-5000

? 150 5001-5150

Commemorative K31, 50 years 1931 – 1981 #001 – 500.

Original serials 270801 – 271300

1)Recommended setup for reloading the 7.5×55 Swiss

A press, Forster (recommended) RCBS Rock Chucker or Dillon 550B (If its RCBS get the Primer Option) Dies for your caliber (RCBS, Redding, Hornady etc.) Spray lubricant and case neck brush, or Castor Oil (recommended)

Wooden or plastic case block to hold 50 cases Powder Dispenser (RCBS) Powder scale Case mouth Funnel Powder Trickler Manual Case Trimmer with collet for your caliber. Wilson (recommended) or RCBS.

Reamer/Champfer for case mouths

Calipers to measure case lengths

Powder and Primers.

Sierra Reloading Manual (recommended)

If you shoot very much you really do need a Case Tumbler.

Dillon or Lyman are the best.

Case tumbler medium, walnut preferred.

———————————————————————————–

I’m posting this here so it’s easier for me to find and access when I send it to the ones who email asking about this.

I’m also going to add to what Dad had originally since I’m getting deeper into this all now with the zfk55.

Added: Keep in mind that new equipment, powders, primers and technology have appeared since this was originally written.

You have to apply this logically keeping in mind that there are new innovations since this was written.

————————————————————————————————

From my Father:

My “platform” is the basis upon which all of my load data begins, and it’s NOT that hard. You can analyze, illustrate, debate and tweak till the cows come home but it all ends with one single base. Your case preparation.

My credentials? 42 years of reloading and 32 of those devoted to the 7.5 Swiss cartridge. Load data of mine that was in use long before the manuals figured out that their own data was erroneous and based on the wrong rifle. Do I have any magic? Absolutely not. Is there anything mysterious or technically difficult to understand about how I do it? Absolutely not. Have I varied one iota from my original “platform” in case preparation? Absolutely not…. and yet I see a supposed mystique surrounding the reloading for this cartridge evoking all kinds of semi confusing answers that are completely unnecessary.

I won’t argue with anyone about presses or dies. This is what works for me, take it or leave it. Want to use a different press or die set? Go for it. After all these years and many thousands of successful rounds downrange, I’m not changing anything, however, advances in technology may now dictate other wise to you.

A) Whatever kind of press you have, using Redding Comp, RCBS dies or your own choice, run the ram all the way up. Turn your sizing/decapping die all the way down against the shellholder. Lower the ram and turn the die down another 1/2 turn or so, maybe even less, but make sure that when you run the ram back up the ram “cams over” at the top of the stroke. This is “full length sizing”. I don’t want to hear about all of the variables in die setting possibilities with all of the other cartridges you use. For the 7.5 Swiss, make your press cam-over at the top of the stroke to begin. Find a better way for youself later? Why not.

Neck sizing? Forget it. After very few times fired in a k31 your case won’t be chambering anyway. Even if you do neck size, your case will have to be hand-fed into the chamber and indexed to exactly the same “o’clock” position every time to be effective. Not all k31 chambers are identical. I do it with a few of my commercial rifles with some success. 7.5 Swiss? Forget it. Its an exercise in futility that won’t shade my loads anyway, and there are at least two local k31 owners that are now believers.

I’ve used a myriad of presses, both fixed and progressive over the years and the RCBS Rockchucker was my mainstay for load data development until the Dillon 550B came along. We now use a Forster almost exclusively for precision reloading.

Though I have a spread of other mfg’s dies, Redding comp is all I use for the 7.5 Swiss. I currently have 6 sets of RCBS as well.

B) Set your decapper to the proper depth allowing just a bit of the tip to appear through the bottom of the shellholder. Screw it in too deeply and you’ll bend the shaft and ruin a case. Lock the die into place.

1) Use a case tumbler or a washing machine to get your brass clean. If its a washing machine, put all the brass in a pillowcase, tie the top and wash them in hot water with a good dishwashing soap. Shake all the water out and let them dry overnight on a towel.

2) TTL…. Trim To Length. Our spec will be 2.179 or less. I suggest you don’t trim much shorter than 2.160.

Ream and champfer the case mouths. If you don’t have that little tool, buy one.

3) Lubing: Use a case lube/pad combo or the new sprays which I consider superior. Plain old Castor Oil works great too (Now preferred). If its a pad, use your fingers to spread the lube evenly over the surface of the pad and roll the cases completely. Use your finger and tip the case mouth down and roll that too. Don’t get lube on the shoulders. This type of lube is non-compressible and can dent your case shoulders upon sizing. Use a mouth brush to get inside, but use it sparingly.

Spray: Using a cookie sheet, line it with aluminum foil and lay your cases down on their sides with all the mouths facing toward you. Holding the can at a 45 degree angle, spray from the rear of the cases toward the mouth allowing spray to enter the case mouths. Using the flat of your hand, roll the cases around and hit the case mouths once more very lightly. If it’s to be Castor Oil, use it sparingly. It goes a long way.

Spray lube and Castor Oil are not of the non-compressible variety so you won’t have a problem with the case shoulders as long as you don’t overdo it..

4) Lightly coat the inside of your die with spray lube. Do NOT do this with paste lube. Put a case in the shell holder and run it up firmly but gently. If you feel any resistance, STOP! Lower the ram and check the depth of your decapper. Check to make sure the inside your die was actually polished at the factory. This is not at all unheard of. I’ve gotten 3 of these over the years and they will not allow you to run the case in.

Assuming your ram cammed-over at the top of the stroke, you should now have a properly sized case that will chamber without any resistance in your chamber.

Have to hit your bolthandle with the palm of your hand to get it to chamber? Projectile seating aside, it won’t be because you didn’t size your case correctly.

I’ve read plenty of rationale on chambering, and (without telling you how many Swiss rifles I have) None of mine chamber other than smoothly and easily, without rapping.

5) Clean your primer pockets with the appropriate tool. I use the small, formed wire brush in a plastic handle meant for this procedure. Seat your primers dead flush with the case base.

6) Projectile seating: It is not at all necessary to crimp for the 7.5 Swiss rifles. Crimping introduces a variable that you don’t need. The grip of the case mouth on the bullet will not be identical every single time, thus, the unwanted variable.

To determine proper seat depth for any given projectile, keep in mind that the measurement is only valid when the contact of the bullet’s ogive and the lands/grooves is determined.

Your manual says OAL is 3.020?… maybe for that bullet that they used, but only for that bullet profile, not all others. Projectile profiles vary from mfg to mfg. So how do you do it?

There are any number of ways, but I’ve always used the same methodology. Take a sized, empty and unprimed, uncharged case, start a bullet into the case mouth leaving it protruding further than is apparently correct. Place it in the rifle’s chamber by hand, ease the bolt into full battery and “smartly” eject it. Measure that OAL and seat it 2 to 4 thousandths deeper. This is a good start. Later, when you’ve become more deeply involved in data gathering, you may want to play with seat depths to find the sweet spot for your cartridge. I have specifics I use regularly. Bear in mind that the k31 has a short throat, and the k31 typically prefers the ogive very close to the lands.

Yes, there are other ways. If you like your way better …….use it.

Once you determine your chambered OAL for that bullet, screw your seating die down until the mouth of an empty case stops the descent and back it out a full turn. Lock the die in place and back out the seater.

That method is only going to work for one bullet profile, and it its a hollow point its not going to be accurate anway since not all meplats are the same even in the same box. Your bullet seater should be indexed behind the tip ahead of the ogive, not on the tip of the bullet. A Sierra 175 MK is not going to be the same as a Berger 175 VLD at all. Both should index on an area ahead of the ogive, but not all ogives are the same distance from either the case mouth or the bullet tip. If you use just the tip you’re going to have two completely different freebores for the same caliber, weight and charge with likely two different results.

Now measure it and decide how far off the lands you want to begin. Note that figure and begin working out your load, adjusting seat depth as you go. But remember that was only for that bullet profile. Change profiles and you’re back to square one.

Find load data that might be in a trusted manual or proven data from the board. Always begin with a lesser load even if the data you find “appears” to be proven.

“Stand up and shoot it like a man!”

Only if Jeff Cooper is watching, otherwise use a bench rest when developing your load data. Use the same rest or bagging methodology every time you shoot. Remove all variables from your data gathering….. and that’s the secret, gents. Consistency. Consistency.

*

Mar 20, 2011 #1

Answering email after email from a dozen different boards is getting really to be a chore, so here it is.

Both Dad and I consider this procedure to be important for Swiss rifles since barrels are hard to come by and very difficult to replace.

Doubly important for those of us who own zfk55’s First, an old email response that will help a lot, and its an evolving explanation.

————————————————————————————————————————————

Ok. Even though the process isn’t rocket science, this isn’t exactly short. I’m posting all of the info I have from a 2 year period of successfully doing this. The main thrust of hBN is not to improve accuracy, but to prolong barrel life. When properly prep’d and slurry treated, your barrel can double and even triple it’s expected accuracy life. These are excerpts from writings and emails to enquirers by my Father.

Every barrel in every rifle here but one has been treated. Not one projectile goes down range that isn’t hBN inpact coated save those for one solitary Moly dedicated rifle.

—————————————————————————————————-

Your bore is going to make a difference right out of the gate. Both Moly and hBN have specific applications. Lab Grade Moly is typically 99.8% pure with a 1 to 3 micron size. hBN (far more preferrable in most bores) is typically negative 5 micron or smaller.

First, hBN. The patent shows it as being most effective on a standard steel bore, and has no effect on a 17-4 S/S Electro Polished bore, this because the negative micron particles cannot ingrain themselves into the surface and create the required ceramic protective coating.

hBN is not susceptible to moisture and thus does not allow corrosion to affect the lands/grooves of the bore. This is a rather large advantage over Moly.

The process is simple. If you’ve ever fired a copper jacketed projectile in your rifle, use a water based copper removal specific such as Wipe Out. Whatever you use, make sure its water based and ammonia free. Once you’ve borescoped and found the bore to be completely copper free, if the bore is .30 caliber, roll a .270 (or whatever, but a bit smaller diameter than your bore) caliber clean swab in a mixture of 100% Denatured Alcohol and hBN. Use a small, sealable pill bottle, glass or plastic to mix and store the slurry. The ratio should replicate a slurry the consistency of whole milk. Run it back and forth through the bore. Within half an hour I fire an impact coated projectile through the bore and that’s it. The bore is effectively ceramic coated.

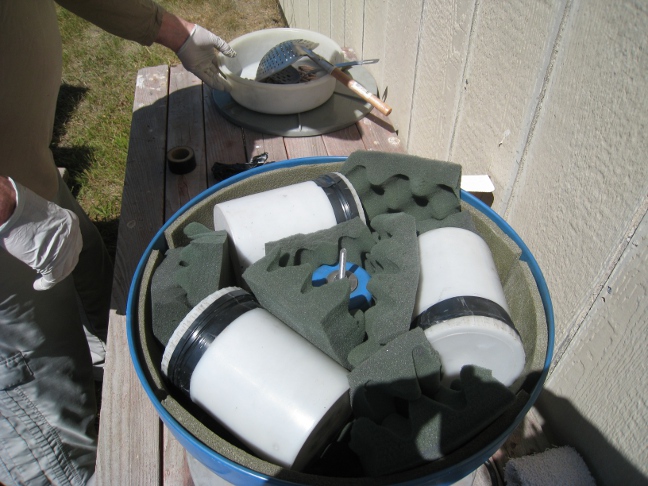

Everyone has a methodology and most involve pill bottles in the tumbler suspended in media. I don’t. I use 16oz (and larger) plastic jars with screw on lids, and not inside the tumbler in in the media. I made a secondary lid for the tumbler/vibrator on a CNC. Its 1/2″ thick Sintra with a 1/4″ deep channel cut into the bottom to fit over the inside and outside edge of the tumbler. A 5/16″ hole is drilled in the dead center to acommodate the shaft and wing-nut. All four jars are spaced evenly around the shaft on top of the lid. The tumbler is empty.

Dillon Commercial

Lyman Standard

All four (or two) jars are filled to the 1/3rd mark with impact coated .177 steel bBBs. The BBs must be washed in Dawn with no additives or cleaned with a Sonic Vibrator and denatured alcohol. Add a nominal 1.5gr of hBN.

Place 50 .30 caliber (or whatever, untouched by human hands) clean projectiles in each jar, add a nominal .5gr of hBN and vibrate for three hours. The jars on top impact coat the projectiles easily 4 times harder and faster than in a pill bottle suspended inside the tumbler in media. Once the lids are screwed down tight, use a 1/2″ wide strip of plastic tape around the area between the lid and the jar. Negative 5 micron hBN is so fine it can potentially find it’s way through the threads.

Use a large slotted spoon, (slotted wide enough to allow the impact coating BBs to fall through, but not the projectile)s to remove the impact coated projectiles from the jars and tumble them in a Terrycloth towel.

We begin by stripping the chambers, throats and bore with Wipe Out. Its an ammonia free, water based bore cleaner that removes literally everything. Carbon, copper, any kind of fouling including Moly. We leave the Foam Type Wipe Out in the bore and throat for about two hours then dry swab everything. We do a follow-up inspection for any copper residue with a Hawekeye Borescope. A complete, 100% copper free bore is essential.

I wash the bullets in very hot, soapy water with Dawn. I use a bowl with a plastic strainer that just fits in it. Once washed, I thorougly rinse with hot water, not cold. From that point I handle the projectiles as little as possible and then only with disposable latex gloves. Assuming you’ve already treated the .177 steel BBs, you can put 50 to 75 .30 caliber or 100 smaller caliber bullets in each jar.

——————————————————————————————————-

(Email update)

Mike, we’ve added to our method just a bit since you read the last email. We now place a thin layer of dense foam in the bottom of the Dillon. the jars are sealed where the top threads down onto the jar with plastic tape to keep any hBN from leaking out. We place the jars on their sides and pack them in with chunks of foam. We place enough foam on top of them so that when the vibrator lid is screwed down they’re trapped tightly. This keeps everything horizontal and the bullets stay on the horizontal position. Works much better and you won’t need a specialty lid for your Dillon. The attatched pics are of one of our smaller vibrators with two of the older jars we original used. We now use the new jars in the larger Dillon, but they do show how the jars are packed and kept horizontal.

With hBN, we consider heat very necessary. We use heat in the form of a Halogen body shop lamp, and the projectiles will come out of the jars almost too hot to handle. Placement of the lamp is critical for the well-being of your tumbler. Too close and you’ll soften the plastic. Vibrate them for 1.5 hours, stop and rotate the jars 180 degrees and continue for another 1.5 hours. Remove them with a slotted spoon and tumble them in a Terry towel a few times. They’ll come out perfect. This horizontal impact coating with steel BBs in a vibrator with no media makes them hit hard and fast, and that’s the secret to perfect coating. Even small tipped bullets come out perfectly with no damage to the plastic tips at all.

———————————————————————————————————–

This original system we developed works well too. The advantage is that you can add media in the tumbler/vibrator and clean cases while impact coating your projectiles. We still do this once in a while, so we often have both methods going at the same time.

A smooth unclouded, unblemished surface tells you that you did it right.

This is the original patent if you’re inclined to read it all. Sometimes its not easy to find the pertinent parts in all of this dry reading, but its all there. We’ve made a study of it, and we’re very successful doing it. http://www.patentstorm.us/patents/71979 … ption.html

(Another Email excerpt)

If not, be safe and use the Wipe Out with a nylon bristle brush, working up a heavy foam and let stand for a few hours.

Dry clean completley with patches or clean swabs.

Take a new .30 caliber cotton swab, or take your old ones and run them through the laundry or dishwasher. Dry completely.

Short switch back to square one:

You’ll get your hBN in a container with a plastic, tape seal around the outside. Open it with extreme care and only long enough to fill a small, sealable pill bottle 1/3rd full. Re-seal the container immediately. Re-apply the exterior tape seal fully and tightly. Store at room temps in a secure place. Spill that container in a room in the house and your wife will be using a bat on you for weeks to come.

(No, I didn’t, and my wife uses Darning Eggs instead of bats)

Screw the swab to the end of a cleaning rod just long enough to run the bore, open the hBN/Alcohol slurry pill bottle, roll the swab in the hBN/Alcohol slurry, (close the hBN bottle immediately) insert into the bore from the breech end if possible. If your rifle won’t acommodate that, run it carefully from the muzzle end. Go all the way through and then work it gently back and forth while slowly withdrawing the swab.

The first impact coated projectile fired through the bore will do the ceramic coating for you, and that’s it. You’ve done it. From that point on fire only impact coated projectiles through that rifle. Cleaning is done with dry patches, no chemicals at all.

For the chamber/throat area, use the right sized swab to fit into each and use Montana Extreme or a like carbon remover. Don’t run any cleaning solvents down the bore.

If you feel the need to do that once in a while, cool…… but make sure you use the clean swab and do the hBN/Alcohol slurry process again. It only takes a few minutes. I unscrew the swab and keep it inside the slurry pill bottle so that it remains uncontaiminated.

To understand how it works, save me a bunch of typing and read the patent.

So how often do you clean an impact coated bore? 50 rounds? 100? 200? 300? 1,000? I don’t know yet. No cleaning required so far, and if the patent is correct it will be a long time to come.

The Hawkeye Borescope always tells the glaring truth about your bore. After each shooting session I pass one dry patch down the bore, just once. So far in any and all of the bores thus treated………. no necessity to clean at all. The most amazing has been the little .22 rifles. hbna.JPG

hbnb.JPG

hbnc.JPG

hbnd.JPG

hbne.JPG

hbnf.JPG

hbnh.JPG

hbni (2).JPG